1961 film, 'Remote Repair and Modification of the HRE-2 Core Vessel' digitized

By Dr. Nick Touran, Ph.D., P.E., 2023-07-05, Reading time: 4 minutes

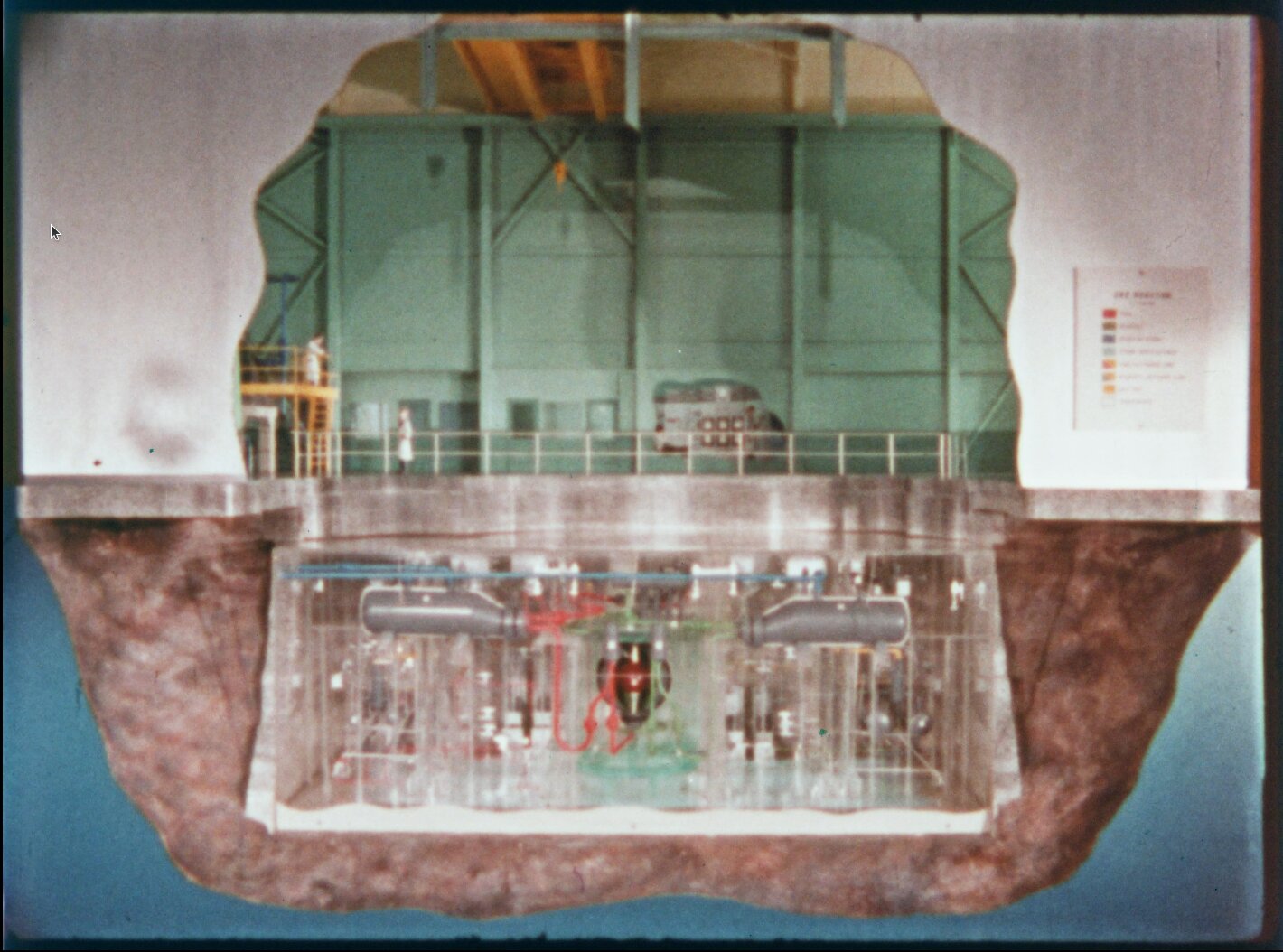

We’re super excited to announce the recent digitization of a 1961 film detailing a major repair of the Homogeneous Reactor Experiment-2 (HRE-2), a fluid-fueled aqueous homogeneous reactor at the Oak Ridge National Lab in Tennessee This reactor was an early predecessor to molten salt reactors. This is the third of four historical nuclear films in our latest batch of 4K digitizations from 16mm film at the National Archives.

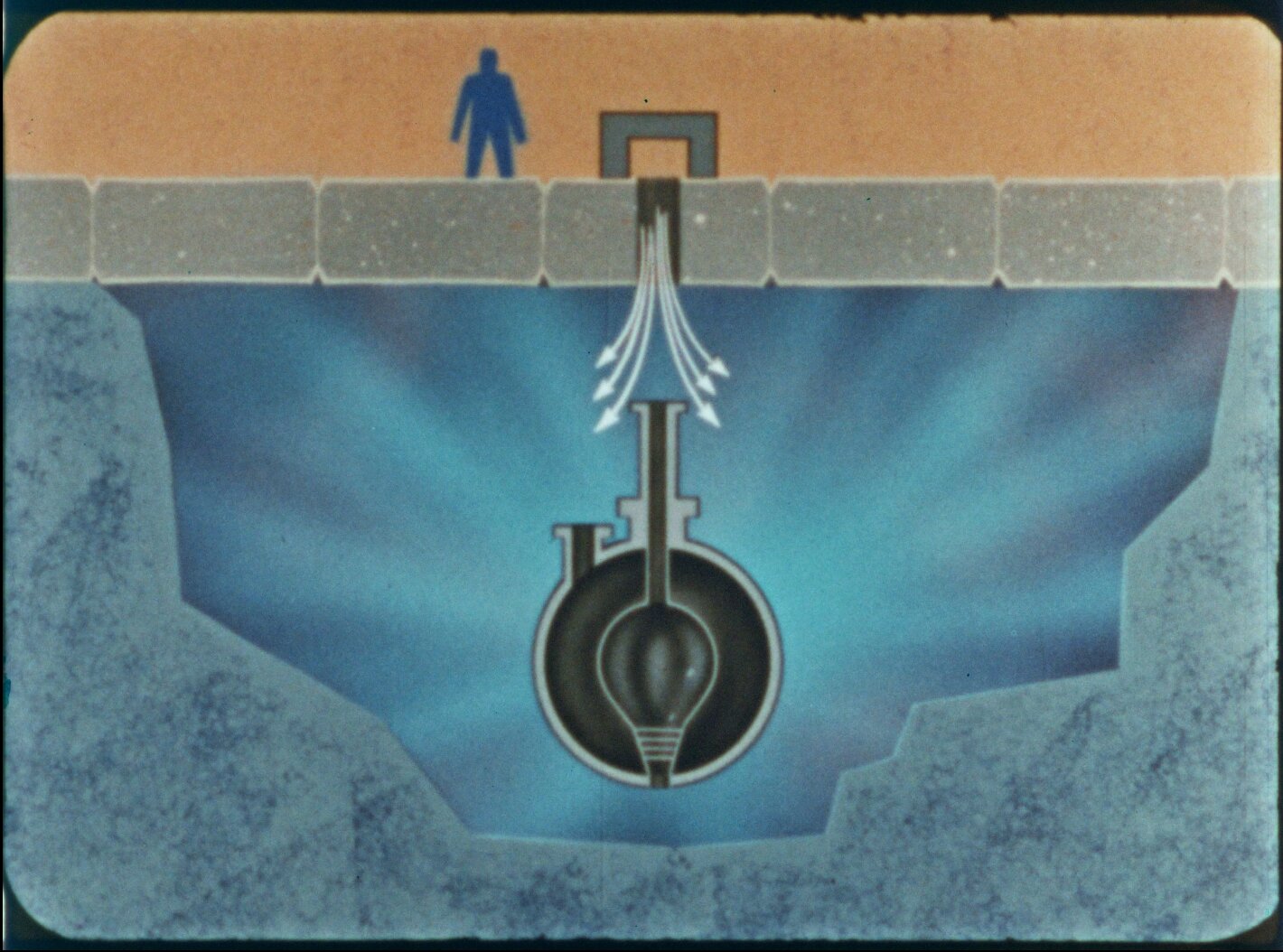

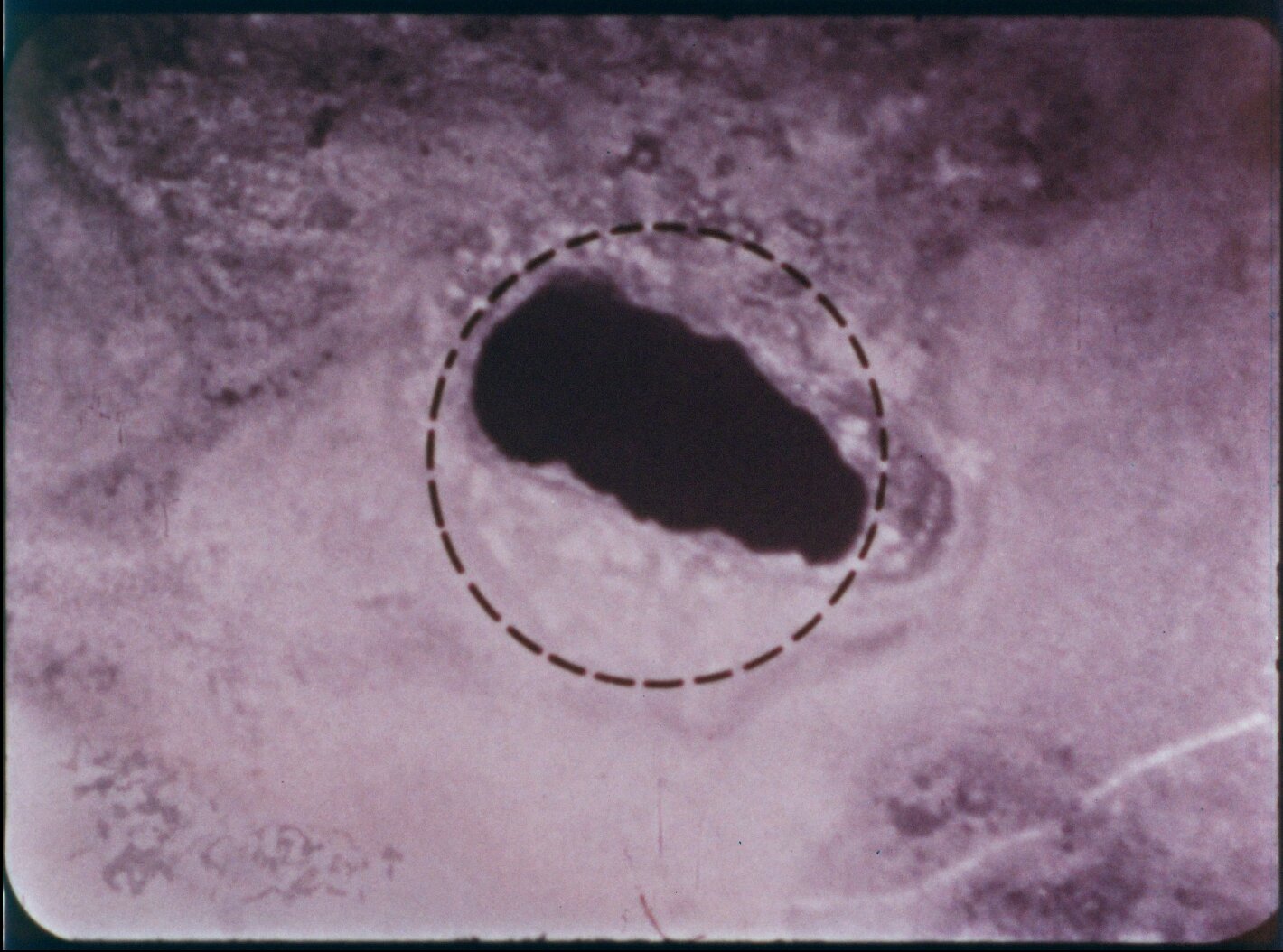

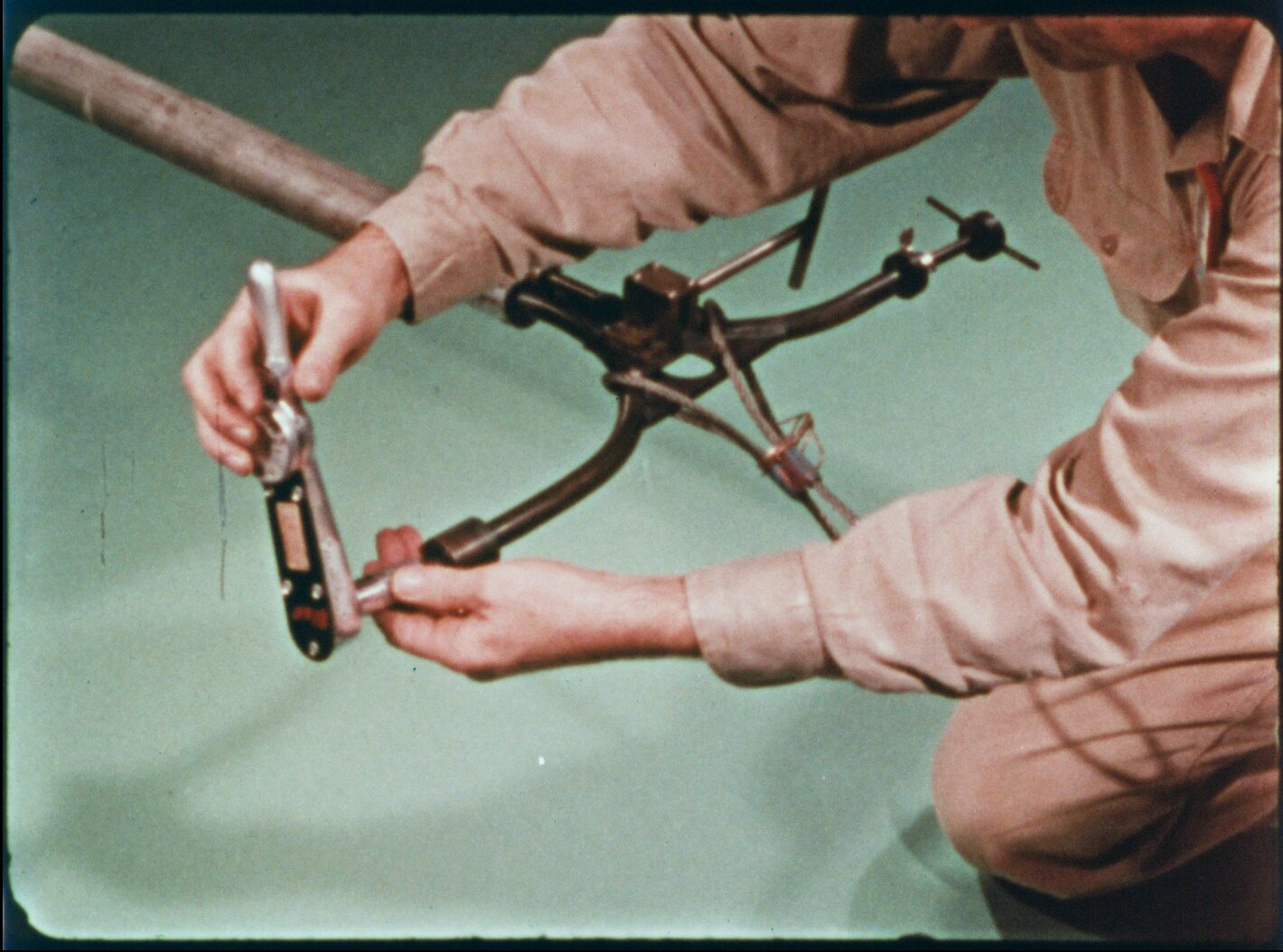

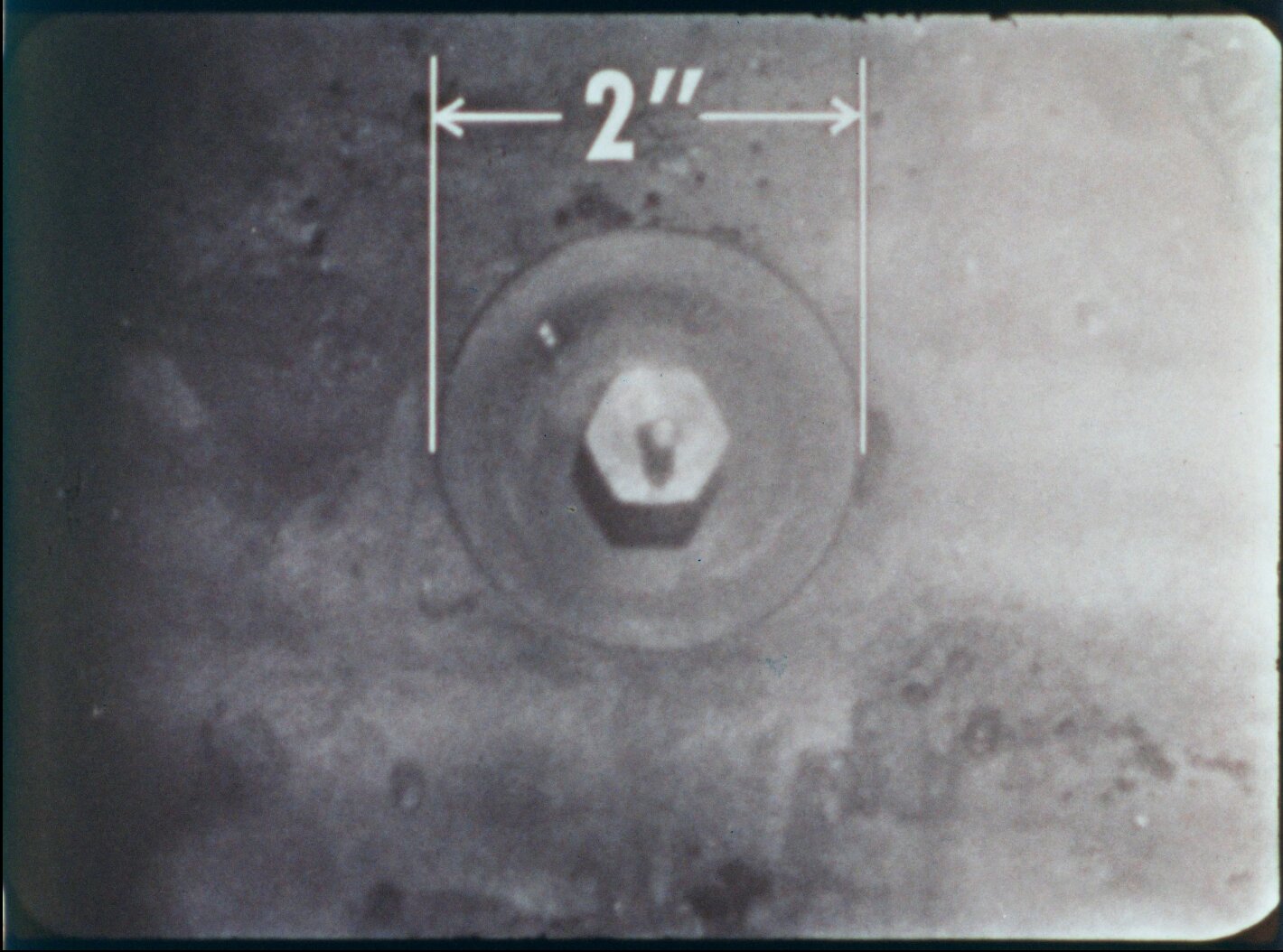

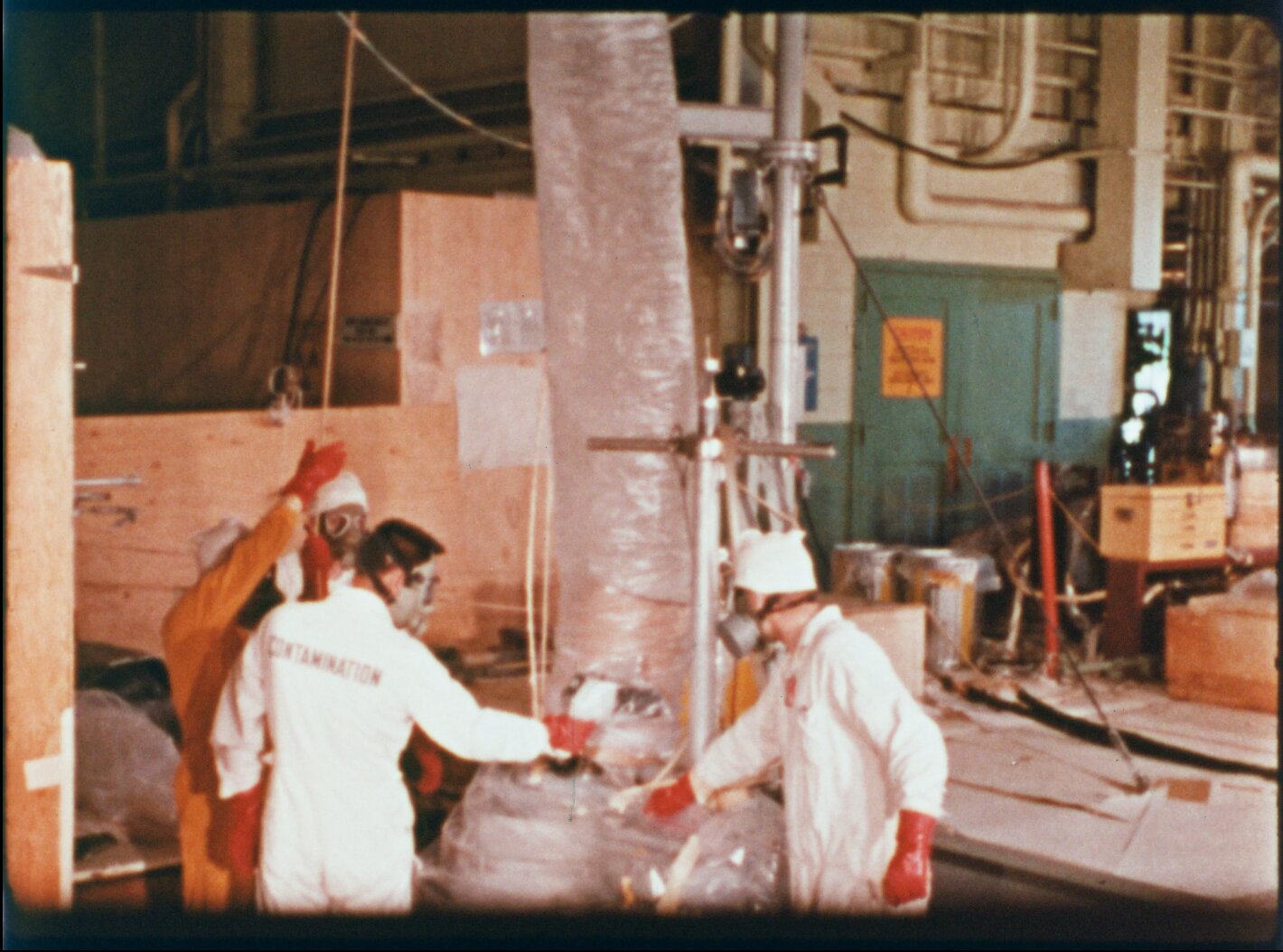

HRE-2 developed a hole that leaked fluid fuel from the core region into the heavy water blanket region. They adjusted procedures and operated in this condition for a while. Later, it developed a second hole and they decided to repair it. This film shows highly specialized tools and equipment allowing them to diagnose and repair the holes remotely. Inside the core the radiation dose rate was a nearly-unbelievable 100,000 R/hr.

I read the story of the HRE-2 vessel leak many years ago in Alvin Weinberg’s autobiography (pg 124), so when I learned that there was an old video describing its repair, I knew it had to be digitized. This is an extremely rare film that probably hasn’t been viewed by hardly anyone since the 1960s… until today!

1961 US Atomic Energy Commission video entitled “Remote Repair and Modification of the HRE-2 Core Vessel” showing the repair of the HRE-2 core vessel after it got two holes in it, digitized by us from the National Archives (NAID 88244)

Catalog description:

Thanks to Ross Koningstein for his help in making this happen.

Read more about HRE-2

Contents of the film by timestamp include:

- 00:00 Intro

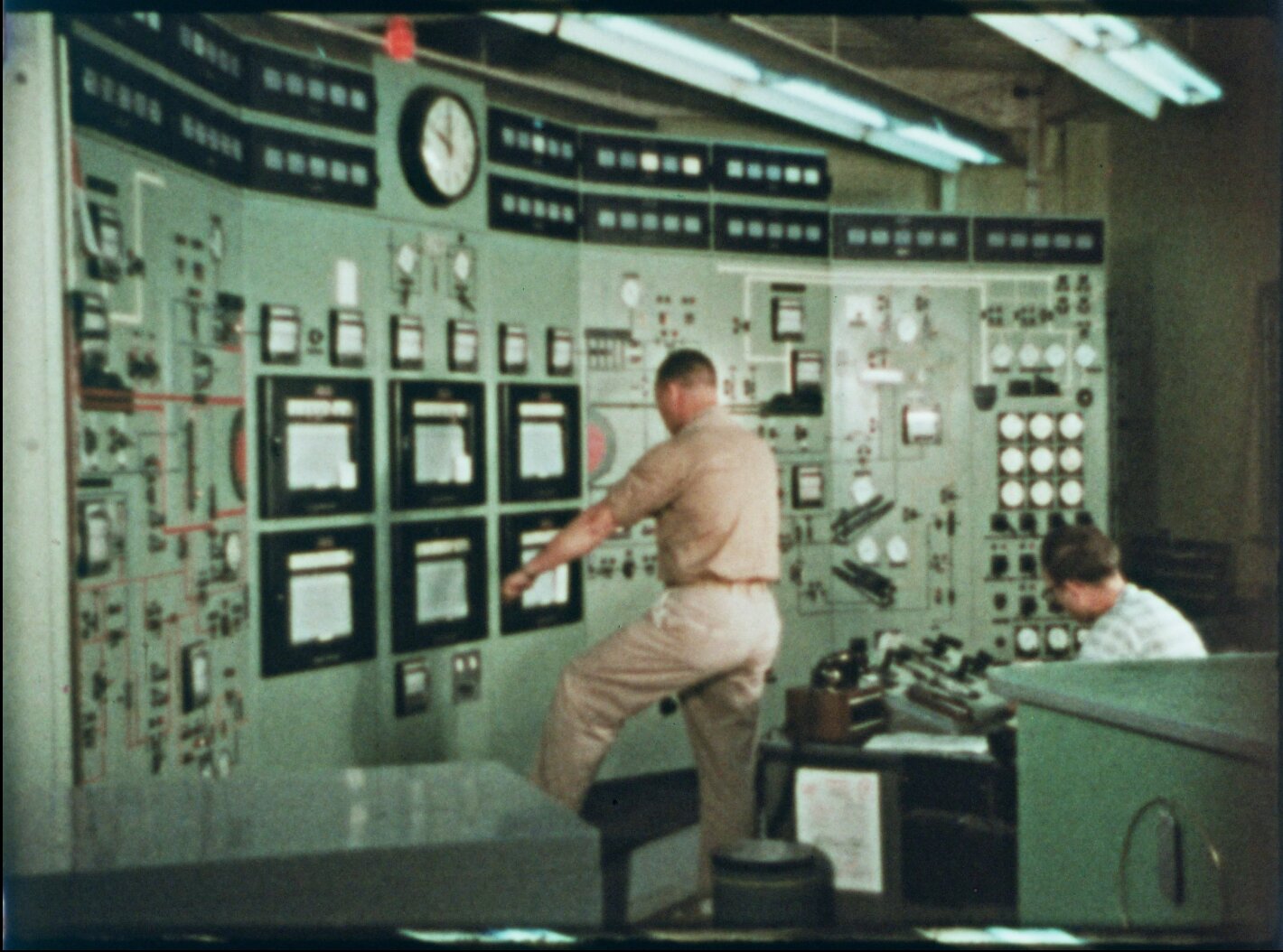

- 01:14 Description of HRE-2 systems

- 03:09 Description of core vessel and first hole

- 04:22 Remote viewing and diagnostics

- 05:02 This is the hole

- 05:18 Full-scale mockup flow tests

- 07:14 Repair and modification plans

- 08:17 Access options and hazards

- 09:10 Development and testing of repair tools

- 10:59 Blanket viewing device

- 11:34 Articulated TV camera

- 12:23 Underwater cutting of diffuser plates

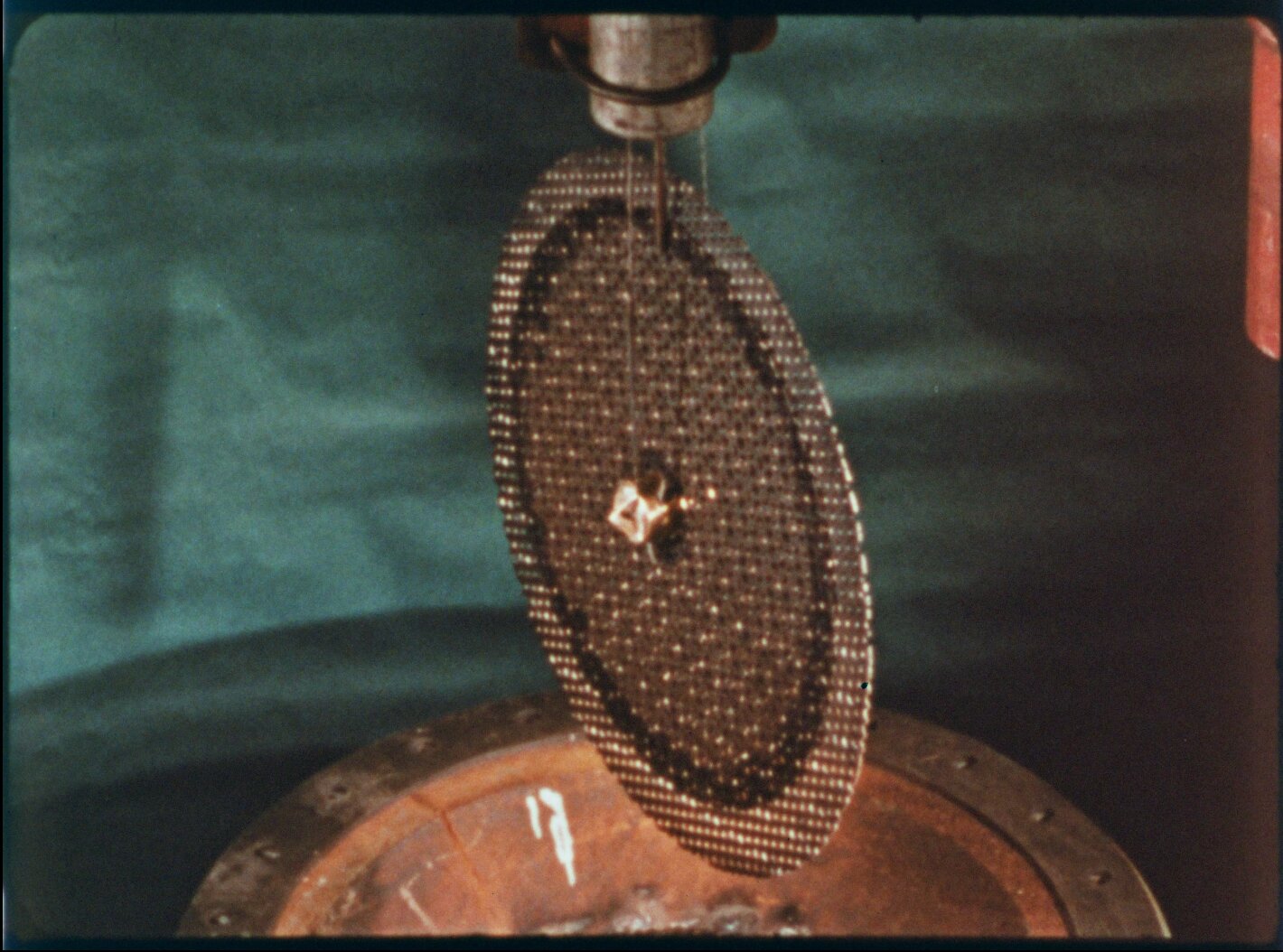

- 14:48 Cleaning tools

- 15:21 Thermoplastic hole impression device

- 16:30 Specimen removal saw

- 17:55 Patch placement tool and patching

- 19:23 Upper hole patch with dissolvable head

- 20:06 Tool contamination precautions

- 20:35 The actual repair

- 21:28 Resuming operation at low power

These are loaded into the youtube video as chapters for your convenience.

See Also

- Our Digital Reactor History Museum

- Our Old Videos page with a running list of the available and yet-to-be-scanned films out there. If you’re interested in helping to get some of these scanned, check out our digitization GoFundMe and/or contact us!

- Tweet announcement of this

About Dr. Nick Touran, Ph.D., P.E.

Nick Touran is a nuclear engineer with expertise in advanced nuclear reactor design, reactor development, and the history of nuclear power. After getting a Ph.D. at the University of Michigan, he spent 15 years at TerraPower in Seattle working on core design, business development, software development, and configuration management. He is now a consultant involved in advising and assisting numerous reactor development and deployment efforts. He is also a licensed professional engineer in Nuclear Engineering.

Nick has been active in public education around nuclear since 2006 as the founder of whatisnuclear.com. He has spoken at numerous institutions, schools, and public events, and was once featured on NPR’s Science Friday. Recently, he has coordinated the digitization of over 45 historical nuclear films.

Reader comments