The Sodium Reactor Experiment (SRE) fuel damage

By Dr. Nick Touran, Ph.D., P.E., 2022-09-27, Reading time: 2 minutes

Background

The Sodium Reactor Experiment was a small sodium-cooled graphite-moderated reactor (SGR) that was built near Los Angeles at the Atomics International Santa Susana Field Laboratory from 1957 to 1964 [2]. It was the prototype for the larger SGR in Hallam, Nebraska. SGRs attempt to use low-pressure high-temperature sodium coolant to achieve high thermal efficiency, good low-pressure safety, and also use a moderator to slow the neutrons down so that they can use low-enriched or even natural uranium as fuel rather than higher enriched fuels typically needed by fast neutron reactors.

What happened?

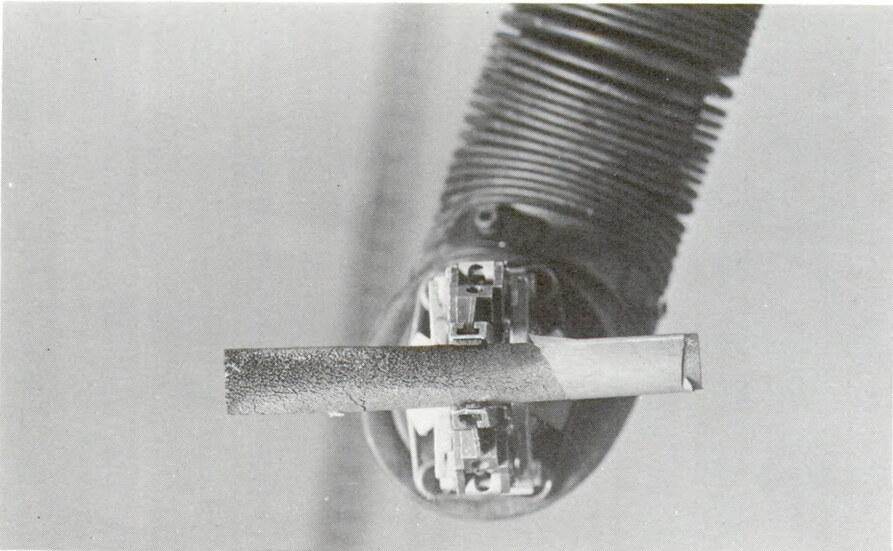

Abnormal temperature readings were recorded in fuel channels during a low-power run of SRE. On July 26, 1959, the run was terminated to investigate. Inspections showed that 13 of the 43 fuel elements had substantial damage.

It was determined that the tetralin service coolant had leaked into the primary sodium coolant. It leaked via a freeze seal on the main primary pump. A nitrogen purge was performed to clean out the tetralin and decomposition products, but some of it remained in the system.

When the next run started up, partial plugging of fuel channels occurred starving the fuel assemblies of their cooling and causing them to go to high temperature. Thermal cycling caused the fuel elements to cycle between uranium alpha-beta phases and to generate low-temperature iron-uranium alloys. Cladding tubes were ruptured due to the fuel expansion.

Lessons

Don’t put tetralin in your sodium-cooled reactors

Due to the problematic reaction products between tetralin and sodium, NaK, nitrogen gas, and kerosene replaced it as a service coolant. Tetralin is no longer used in sodium-cooled systems.

Monitor for fission product gasses during operation

Xenon-133 fission products were found in large quantities in the cover gas above the core. Monitoring for this could have detected fuel failure earlier and led to a faster response with less damage. Cover gas monitoring systems are now typical in sodium-cooled reactors.

Add flux/power deviation circuits

A flux/power deviation circuit was added to SRE that could monitor for large mismatches between heat generation and heat removal, providing a signal to the plant protection system to shut down the reactor if a threshold is exceeded.

Legacy

People in L.A. are still suing the company that bought the company that bought the company that ran this experiment. Additionally, after this and Hallam’s mediocre overall performance, the concept of graphite-moderated sodium-cooled reactors fell out of favor, and is mostly forgotten today. But honestly it’s a pretty good reactor concept.

References and additional reading

- SRE Fuel Element Damage Final Report 1961

- Sodium Reactor Experiment

- Sodium Graphite Reactors by Chauncey Starr, 1958

This page is a part of our Safety Minute collection. You can edit it or add more on GitHub.