The Fermi-1 core melt

By Dr. Nick Touran, Ph.D., P.E., 2022-09-26, Reading time: 1 minute

What happened?

The Fermi-1 SFR had encountered some abnormal temperature measurements and suspected a flow blockage. To investigate, they moved some assemblies around and came to power. On October 5, 1966, at about 30% full power, radiation alarms went off and the reactor was shut down.

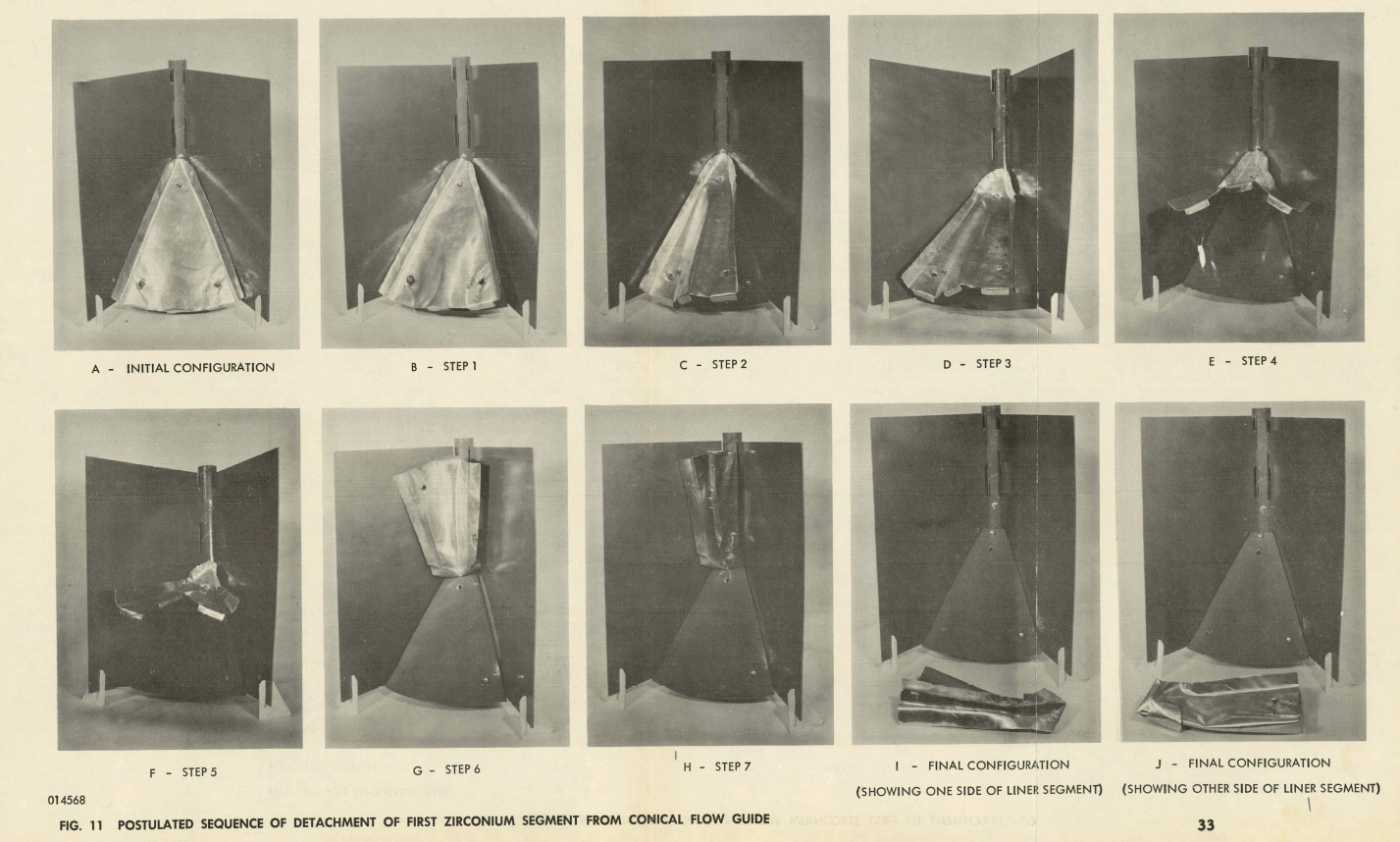

Two assemblies had partially melted because the coolant flow had been 97% obstructed from below. It was determined that a zirconium segment (installed in a conical flow guide/core catcher in 1959 to mitigate vessel break/complete loss of coolant) had broken off and caused the blockage.

Lessons

-

Design your inlets to be difficult to block

-

Don’t put stuff that can break off and block things in your core

-

Be able to detect flow blockage early with instrumentation and analysis

A computer system (Malfunction detection analyzer) was planned to be installed to evaluate reactivity every 5 seconds and alert operators of any deviations (as small as 2 cents) from expectations in power, flow rate, and inlet temperature

Legacy

Most inlet nozzles since Fermi-1 have featured bayonet-style inlets with holes on the sides so as to make it much more difficult geometrically for a loose part to significantly block flow

References and additional reading

This page is a part of our Safety Minute collection. You can edit it or add more on GitHub.