The Browns Ferry Fire

By Dr. Nick Touran, Ph.D., P.E., 2022-09-27, Reading time: 2 minutes

What happened?

On March 22, 1975 at the Browns Ferry plant in Alabama, a worker was inspecting a temporary seal around electrical cable in the cable spreading room, directly under the control room. The permanent seal had been removed to allow additional cables to be run due to a design modification. The temporary seal material was highly flammable, and there was a pressure differential between the reactor building and the cable spreading room.

The worker used a lit candle, holding it up to the seal of interest. The idea was that if there was a leak, the flame would quiver notably in the draft. Well, as you can imagine, the candle was sucked in towards the reactor building and ignited polyurethane seals and cables.

The worker tried to extinguish the fire with a flashlight and then portable extinguishers but did not succeed. The fire spread rapidly in the cable spreading room in the Unit 1 reactor building. At the time, workers were not allowed to use water to extinguish electrical fires. This practice has been changed [6].

Many cables related to the control of Units 1 and 2 were damaged. The operating personnel shut down Unit 1 manually and cooled it using a remote manual relief valve, the condensate booster pump, and control rod drive system pumps.

While attempting to restore makeup water with the operable systems, the core coolant level dropped from a normal 201 inches above the core to 43 inches. Decay heat was boiling away about 240 gallons of water per minute. Only about 1 hour of time was remaining before the core was uncovered [6].

Lessons

- Don’t use open flames to detect air leaks

- Allow use of water to extinguish electrical fires

- Don’t use flammable materials for seals or insulation

- Reduce common-mode failure mechanisms in control systems

Legacy

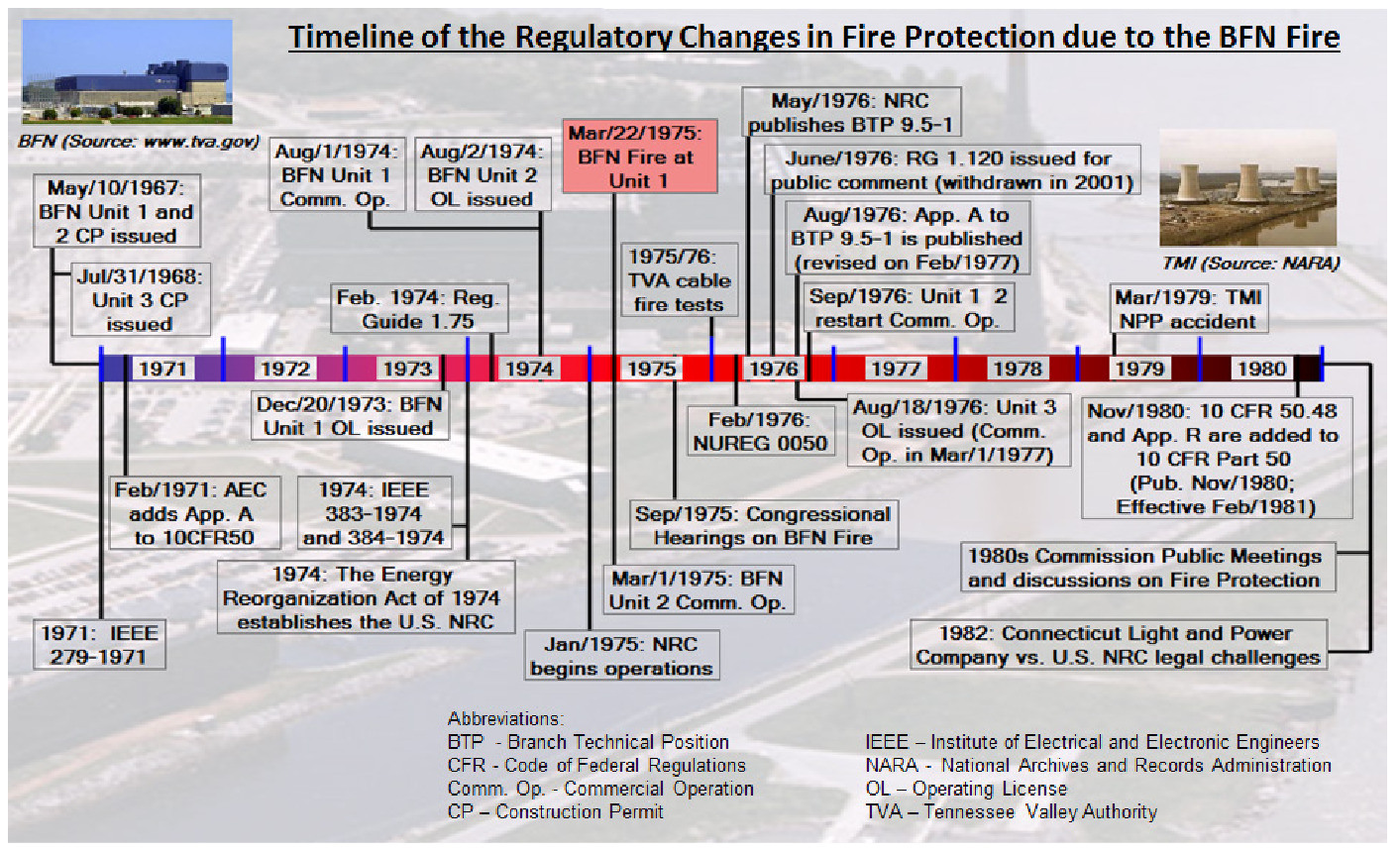

An astounding amount of changes in fire protection occurred after the Browns Ferry fire.

References and additional reading

- The Browns Ferry Nuclear Plant Fire of 1975 and the History of NRC Fire Regulations: DVD (NUREG/BR-0361, Supplement 1) (2009)

- NUREG/KM-0002 The Browns Ferry Nuclear Plant Fire of 1975 Knowledge Management Digest (2014)

- FIRE AT BROWNS FERRY NUCLEAR PLANT FINAL REPORT OF PRELIMINARY INVESTIGATING COMMITTEE May 7, 1975

- Bulletin 75-04A: Cable Fire at Browns Ferry Nuclear Power Station April 3, 1975

- NOVA video on the Browns Ferry fire

- Presentation on Browns Ferry fire

- Recommendations related to Browns Ferry Fire (1976)

This page is a part of our Safety Minute collection. You can edit it or add more on GitHub.