Just digitized: a 1962 film featuring the PM-1 radar-powering nuclear microreactor in Wyoming

By Dr. Nick Touran, Ph.D., P.E., 2023-07-03, Reading time: 7 minutes

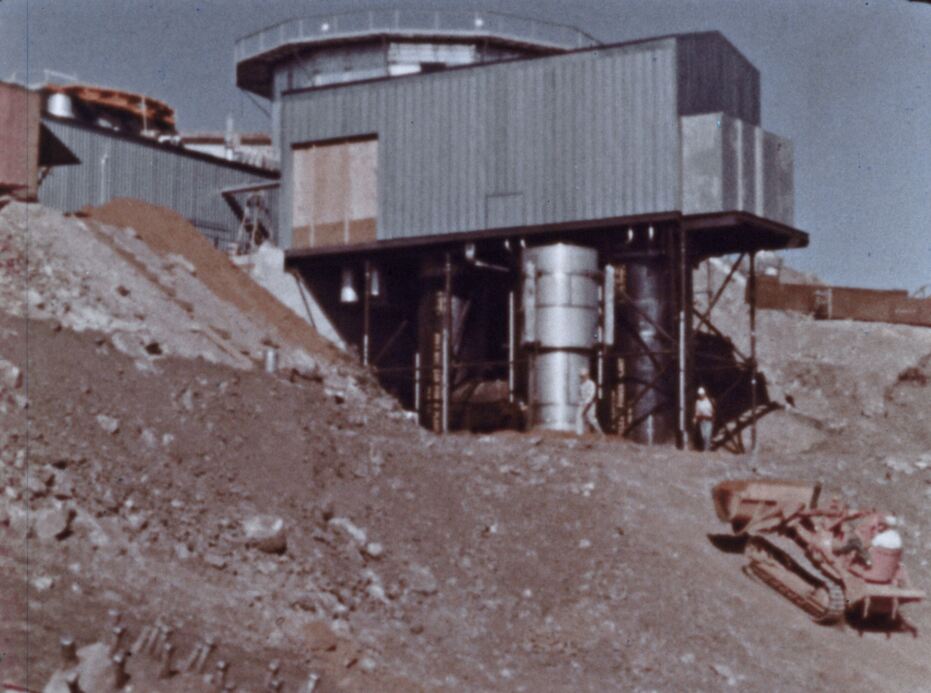

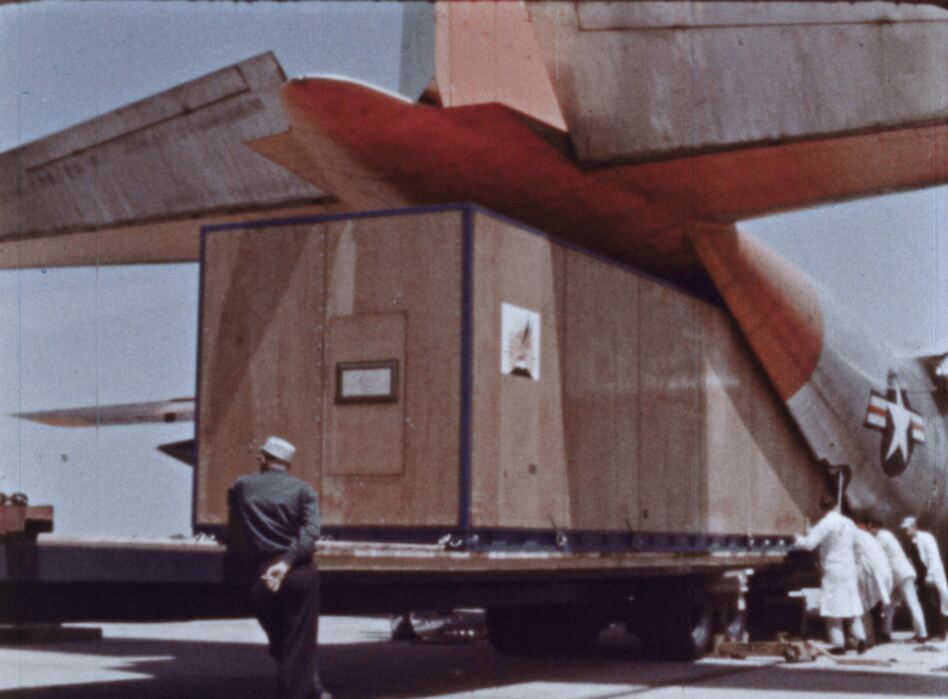

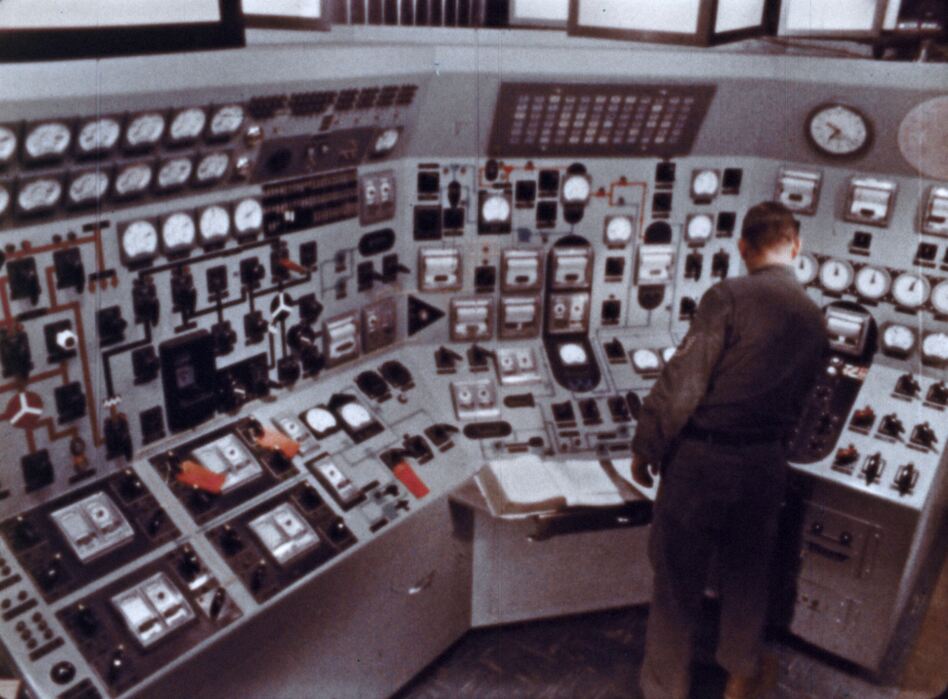

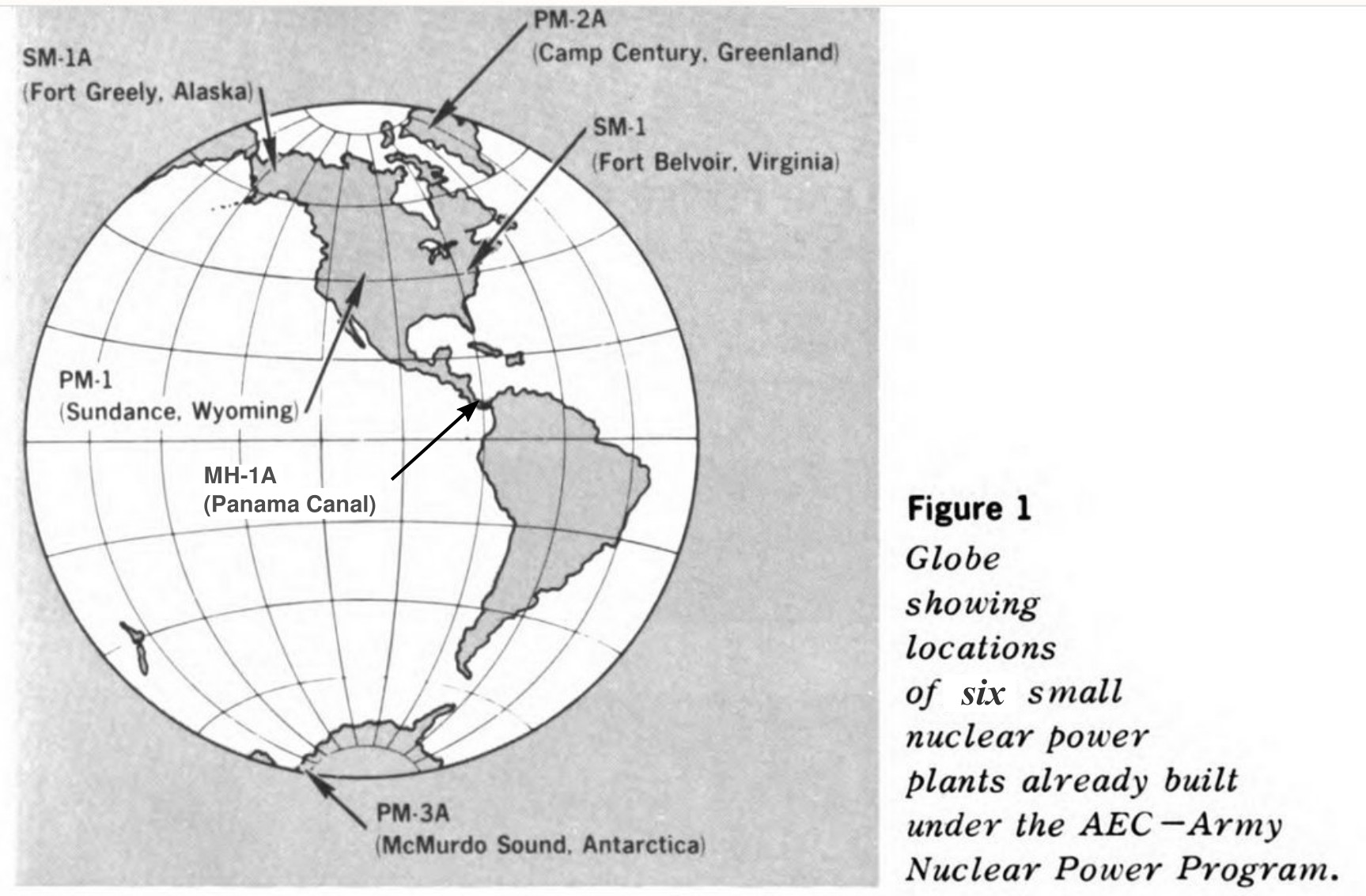

We’re extremely excited to announce the first of four historical nuclear films in our latest batch of 4K digitizations from 16mm film at the National Archives. It features the 1 MWe PM-1 military microreactor, a small modular reactor that the US Army manufactured and tested in a factory, disassembled into 16 modules, and air-lifted to the closest airfield by C-130, trucked to site, re-assembled, and then powered a remote Cold War radar station back in 1962. It had direct air cooling, meaning it did not need to be near any water supply. It was designed to be disassembled, moved, and re-assembled as necessary. No field welding was needed for re-assembly. It was a PWR that could be operated by a crew of 2.

1962 US Atomic Energy Commission video about the PM-1 military microreactor, digitized by us from the National Archives (NAID 88220)

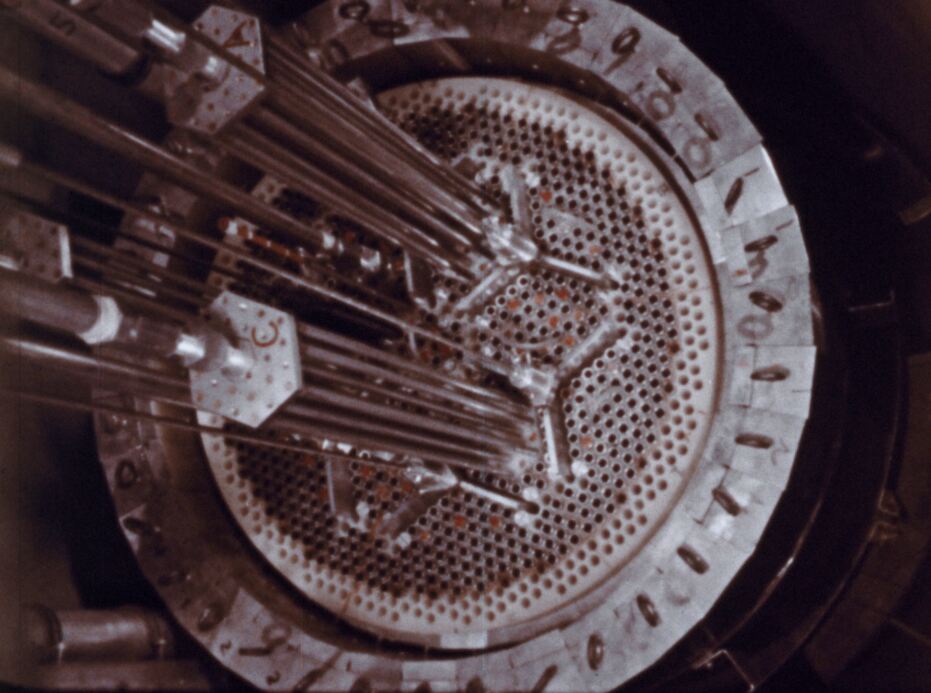

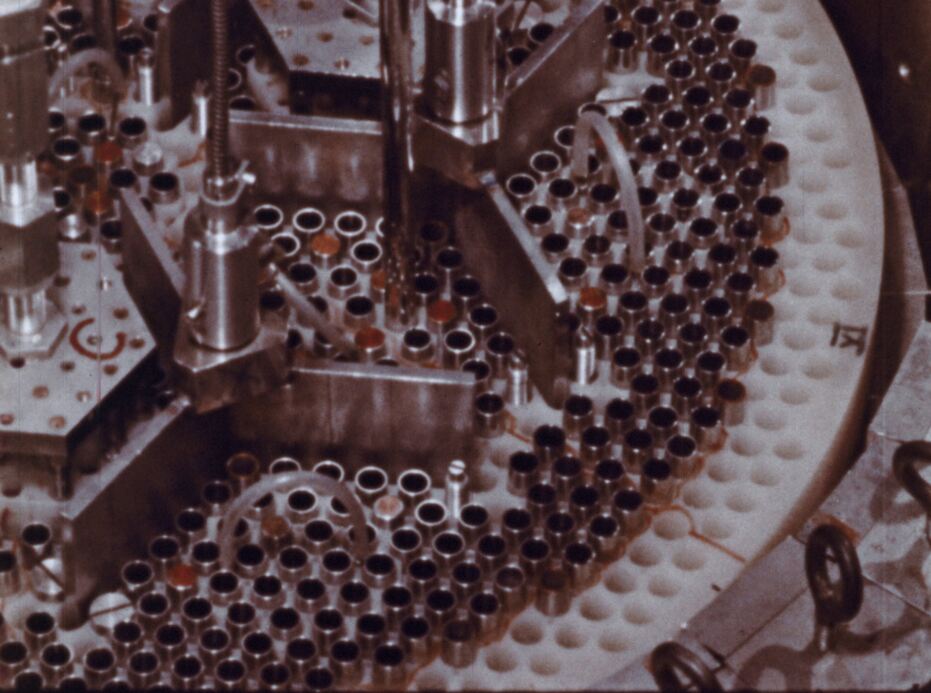

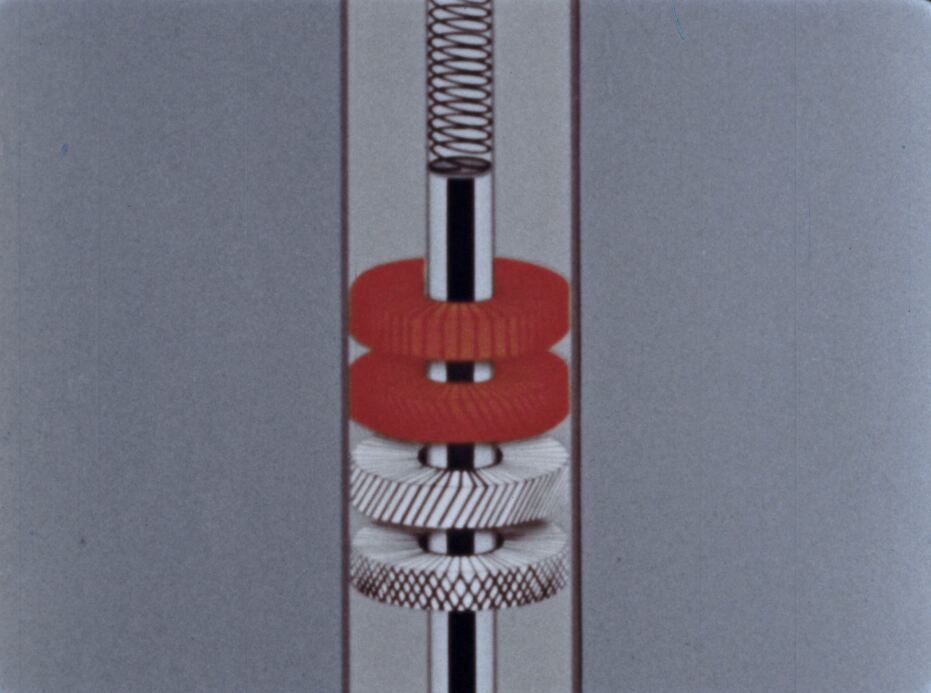

Catalog description: A filmed story of the PM-1 nuclear power plant (a pressurized water system), a joint project of the USAEC and the U. S. Air Force, which supplies the power for the radar and space heating of a remote Air Defense Command radar station in Wyoming. The film breaks down the types and contents of 16 air transportable packages, a total weight of about 30,000 pounds: reactor, steam generator, waste tank, heat-transfer apparatus, control room, turbogenerator, etc. Details are given on major components and the design and operation of the system by information on: 741 nuclear fuel tubes in 7 fuel bundles, the "flow" of primary water, the secondary water, details on the makeup of the fuel element tubes, criticality testing, nature of the control rods, tests to determine heat transfer and flow characteristics. The film recounts the airlift of the packages, erection and assembly of the power plant, the work to achieve criticality, and the varied safety controls.

Thanks to Ross Koningstein for his help in making this happen.

Read more about PM-1

- PM-1 Nuclear Power Program First Quarterly Report (1960)

- PM-1 NUCLEAR POWER PLANT PROGRAM. Quarterly Progress Report No. 2 for June 1 to August 31, 1959

- PM-1 NUCLEAR POWER PLANT PROGRAM 3RD QUARTERLY PROGRESS REPORT FOR SEPTEMBER 1 TO NOVEMBER 30, 1959

- PM-1 NUCLEAR POWER PLANT PROGRAM. Quarterly Progress Report No. 4 for December 1, 1959 to February 29, 1960

- PM-1 NUCLEAR POWER PLANT PROGRAM. Quarterly Progress Report No. 4 for December 1, 1959 to February 29, 1960

- PM-1 NUCLEAR POWER PLANT PROGRAM 5TH QUARTERLY PROGRESS REPORT FOR MARCH 1, 1960 TO MAY 31, 1960

- PM-1 NUCLEAR POWER PLANT PROGRAM. Sixth Quarterly Progress Report, June 1, 1960 to August 31, 1960

- PM-1 Critical Experiments and Zero Power Testing (1961)

- PM-1 Design Analysis (from Proceedings of the ANPP Reactor Analysis Seminar)

- Description of PM-1 criticality in Annual report to Congress - U.S. Atomic Energy Commission. 1962.

- PM Research and Development Program: 1st Quarterly Progress Report, April 15, 1961 to June 30, 1961

- PM RESEARCH AND DEVELOPMENT PROGRAM. Quarterly Progress Report No. 8, January 1, 1963 to March 31, 1963

- Power Reactors in Small Packages

- Record of Decision FORMER SUNDANCE AIR FORCE STATION, PM-1 REACTOR SITE OFF-SITE RELEASE (2011)

As for what happened in the end, the PM-1 Final Summary Report explains the situation clearly. This report contains the lessons learned after operating the military microreactor for 4 years. It highlights all the unplanned outages, maintenance costs, and lists the performance of each individual system. It’s highly readable, but to summarize briefly:

- The reactor was difficult to perform maintenance on because of its compactness. The operators recommend designing the next microreactor with maintenance requirements satisfied first, and then compactness requirements

- The conventional steam plant cause roughly half of the unplanned outages and required a lot of maintenance, leading the authors to suggest that perhaps a non-steam approach is needed at this small scale (e.g. other energy conversion systems).

- The nuclear instrumentation system was oversensitive and overcomplicated for a field plant.

- The HVAC system and building design were wholly inadequate

- It was difficult to maintain qualified staff to operate and maintain the reactor

- The reactor was used as a training reactor for crews headed to Antarctica to operate the sister plant PM-3A, which reduced PM-1’s overall performance.

The best zingers inside include:

In an attempt to correct some of these original design oversights, several modifications and additions have been made to the plant which have made it virtually a stationary plant. Consequently, the Air Force now has a plant that is neither portable nor easily maintainable or operable.

Factors that have resulted in this high cost of power production are numerous; however, many of these costs could be reduced or brought into a realistic value by equating a plant such as the PM-1 to a compatible mission. The problems such as overmanning, excessive modification requirement, training requirement due to the policy of giving maximum training to the majority of the crew members, loss of personnel by premature transfers, operating the plant below capacity, and excessive down time (especially during the first 2 years of operation for design improvement) have all added up to present a dim economical picture of nuclear power production.

Note: I obtained this report through a FOIA request 😎.

Contents of the film by timestamp include:

- 00:00 Intro

- 02:30 Package (module) descriptions

- 03:04 Primary system modules

- 03:23 Secondary system modules

- 03:41 Turbine/generator module

- 03:55 Switchgear module

- 04:43 Heat transfer equipment module

- 05:21 Maintenance module

- 05:50 Decontamination and water chemistry module

- 06:22 Animations of design

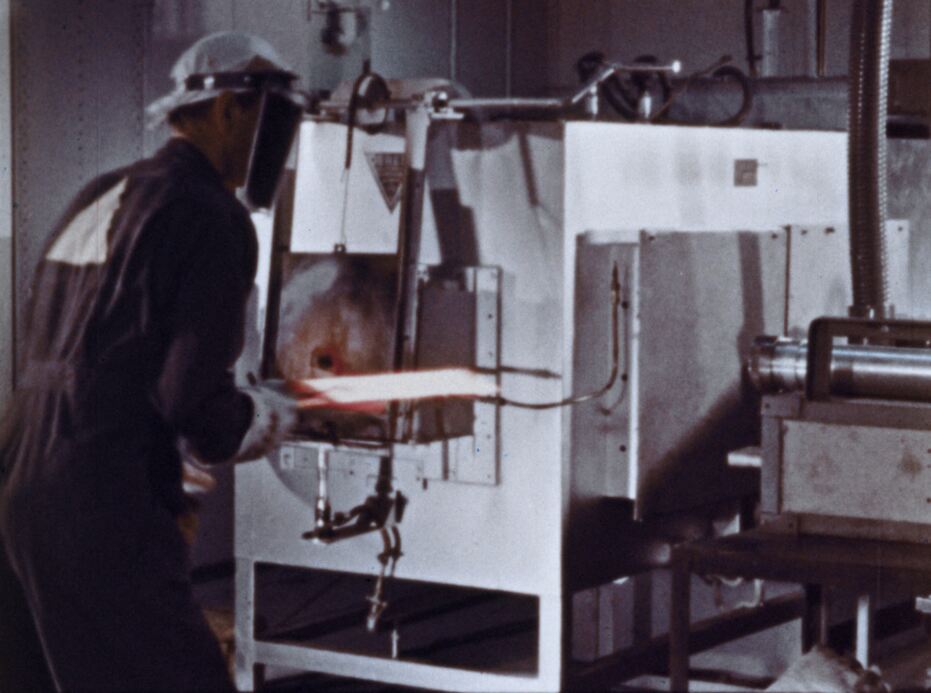

- 08:37 Fuel element fabrication

- 10:00 Core testing in the critical facility

- 12:20 Magnetic jack control rod drives

- 13:01 Flow testing in 1/4 scale model

- 13:27 Factory fab and initial assembly

- 13:51 Airlifting the reactor and flight testing

- 15:10 Field re-assembly

- 15:45 Startup testing and criticality

- 17:10 2-person operation team

- 17:40 Safety and reliability

- 19:05 Summary

These are loaded into the youtube video as chapters for your convenience.

See Also

- Our Digital Reactor History Museum

- Our Old Videos page with a running list of the available and yet-to-be-scanned films out there. If you’re interested in helping to get some of these scanned, check out our digitization GoFundMe and/or contact us!

- A tweet about this announcement

About Dr. Nick Touran, Ph.D., P.E.

Nick Touran is a nuclear engineer with expertise in advanced nuclear reactor design, reactor development, and the history of nuclear power. After getting a Ph.D. at the University of Michigan, he spent 15 years at TerraPower in Seattle working on core design, business development, software development, and configuration management. He is now a consultant involved in advising and assisting numerous reactor development and deployment efforts. He is also a licensed professional engineer in Nuclear Engineering.

Nick has been active in public education around nuclear since 2006 as the founder of whatisnuclear.com. He has spoken at numerous institutions, schools, and public events, and was once featured on NPR’s Science Friday. Recently, he has coordinated the digitization of over 45 historical nuclear films.

Reader comments