The Heavy Water Components Test Reactor and the Heavy Water Power Reactor Program

A 1962 film about the US effort to develop natural-uranium heavy water power reactors

By Dr. Nick Touran, Ph.D., P.E., 2025-02-10, Reading time: 18 minutes

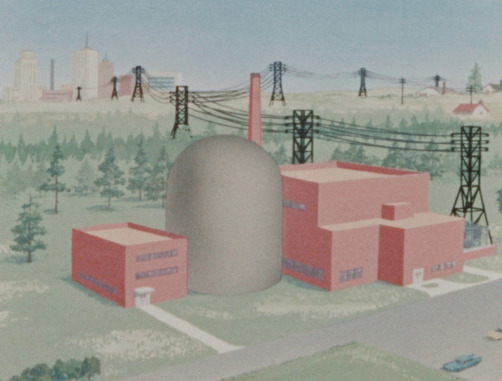

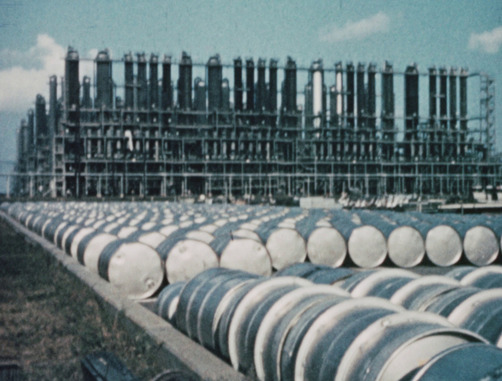

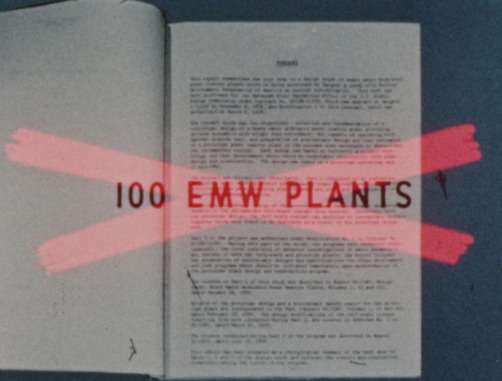

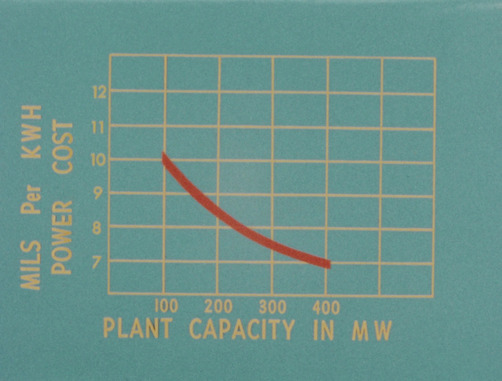

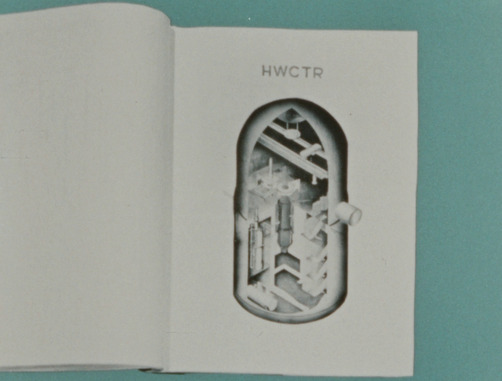

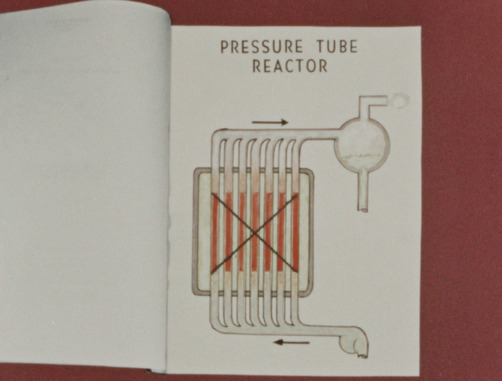

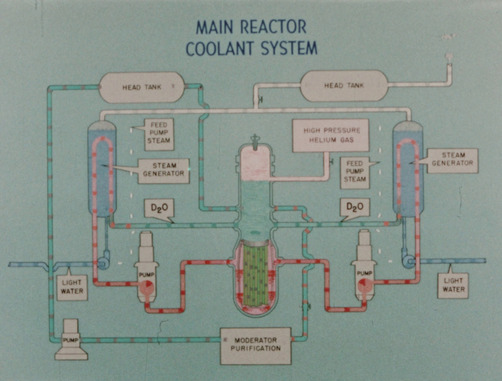

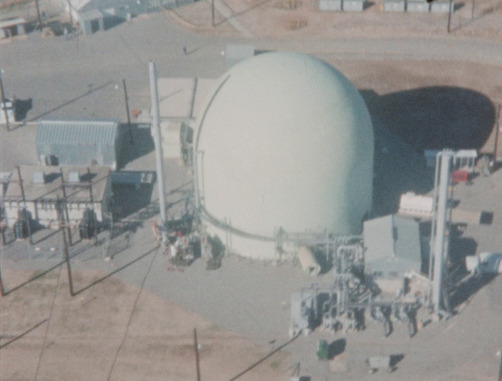

In 1956, the US Atomic Energy Commission commissioned a study on the development of heavy-water moderated natural uranium fueled power reactors with the objective of producing low-cost commercial electricity. Since these reactors do not require any enrichment, it was thought that they could be cost competitive with fossil fuel power plants. To obtain more credible data, the Heavy Water Components Test Reactor (HWCTR) was built. This film describes the Heavy Water program and the HWCTR.

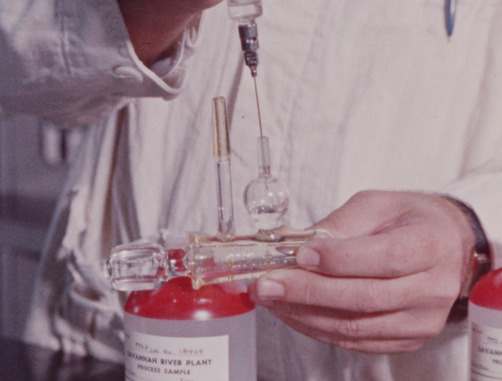

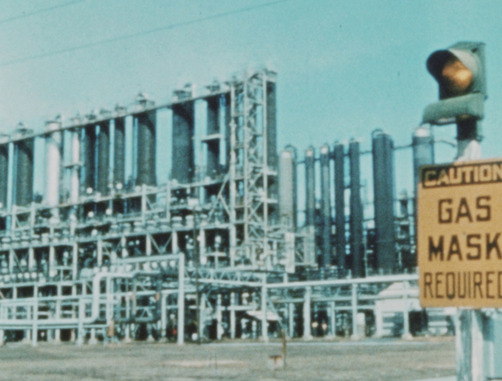

The Savannah River Site was already making 1000 tons of heavy water/year for the weapons program and had dropped the cost from $70/lb to $28/lb. At these rates, it was conceivable to make cheap power plants.

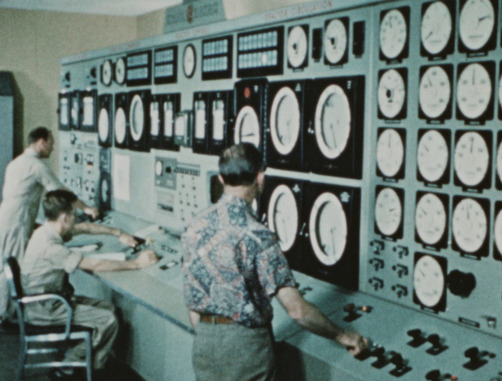

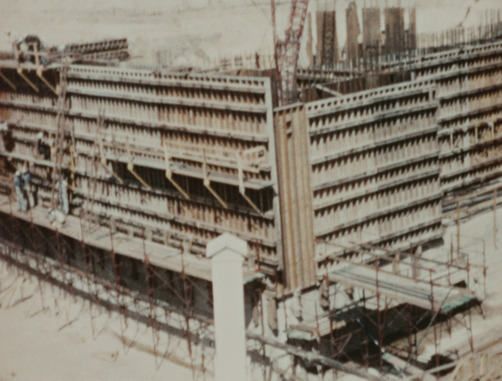

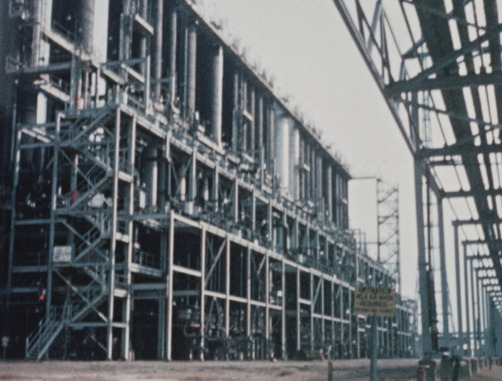

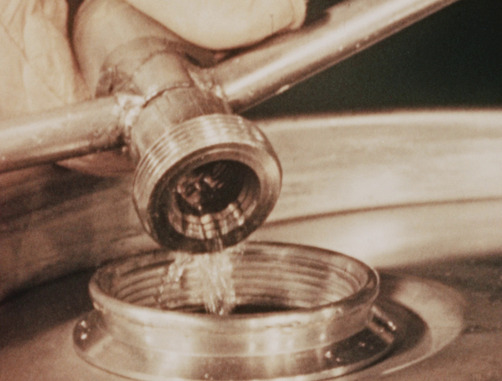

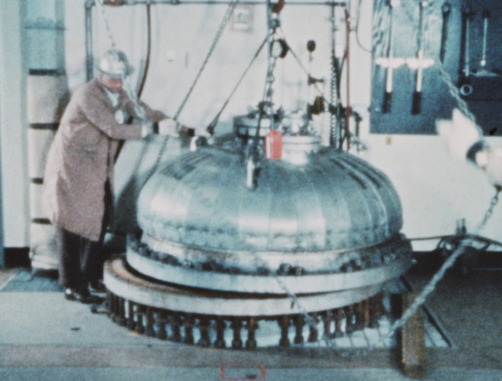

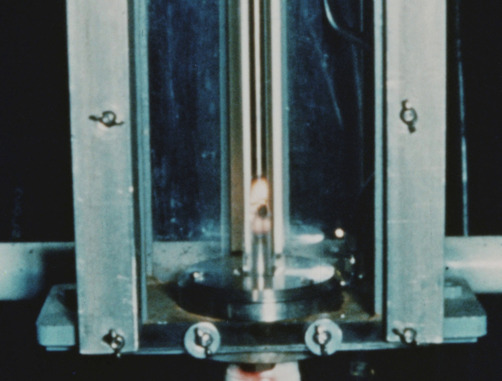

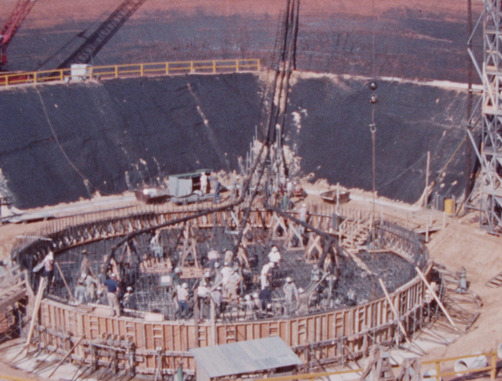

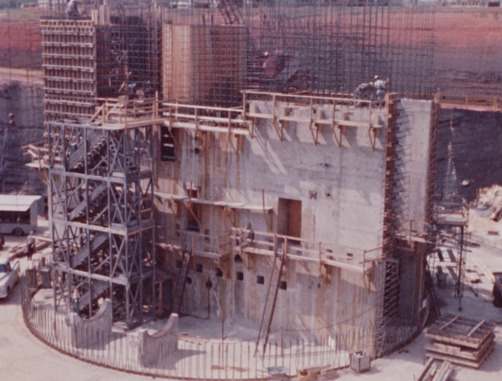

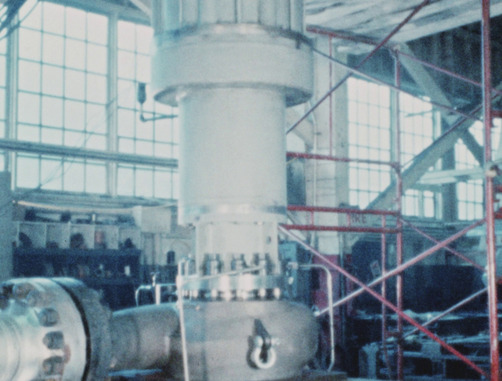

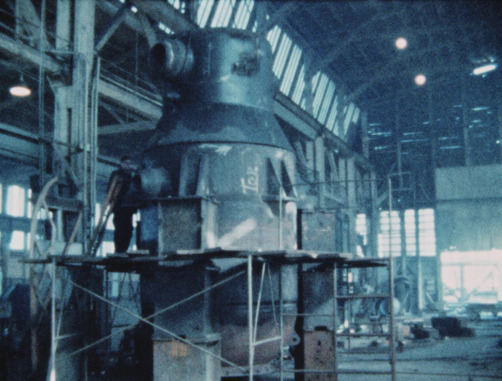

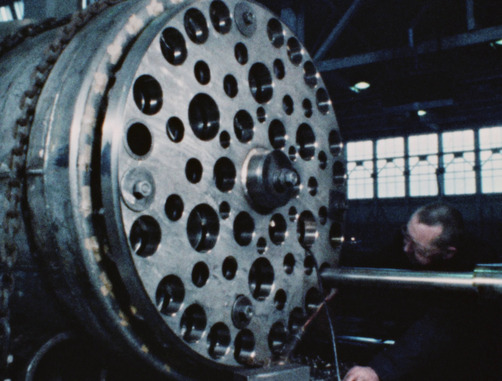

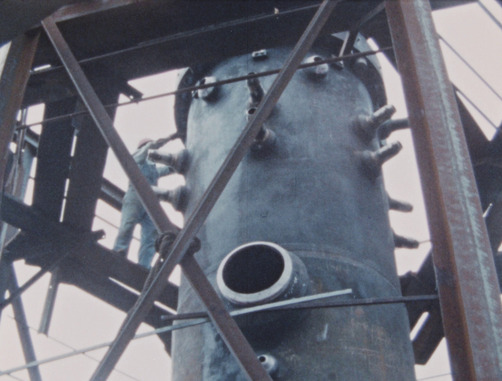

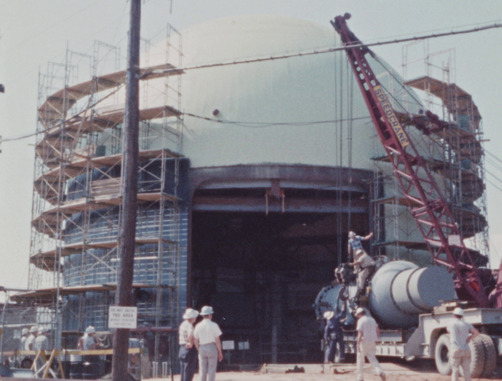

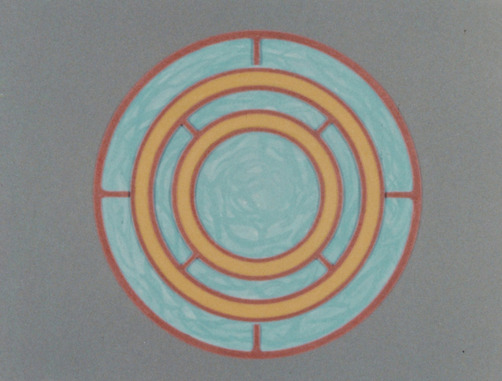

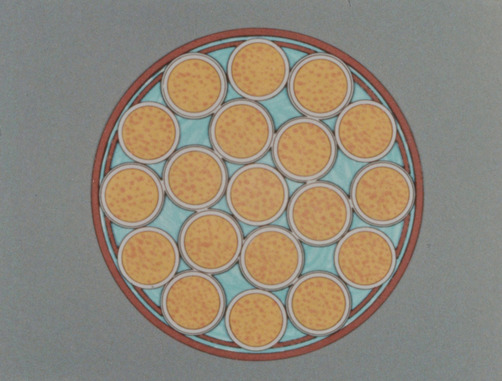

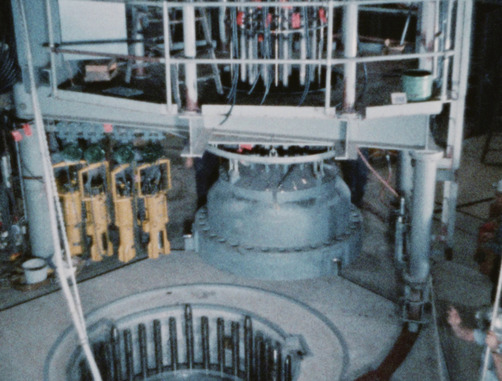

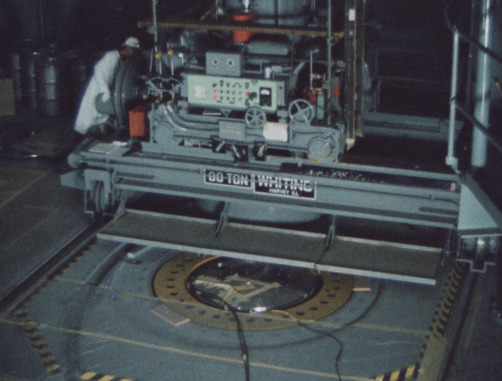

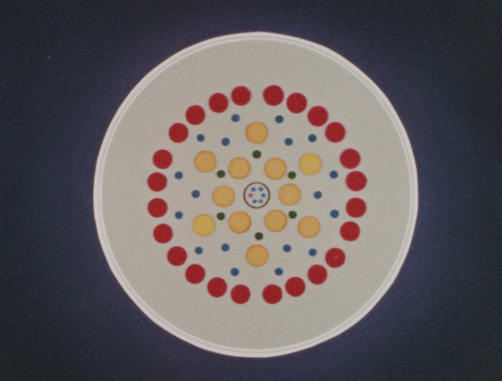

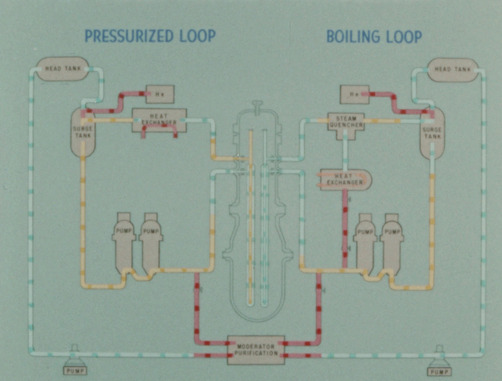

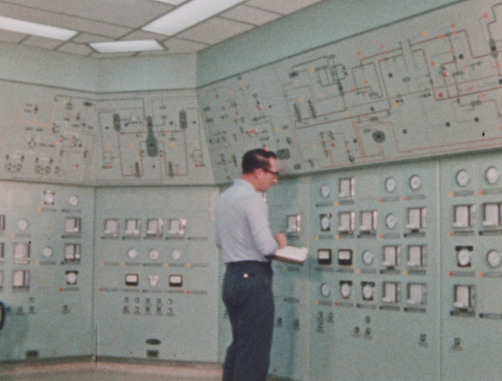

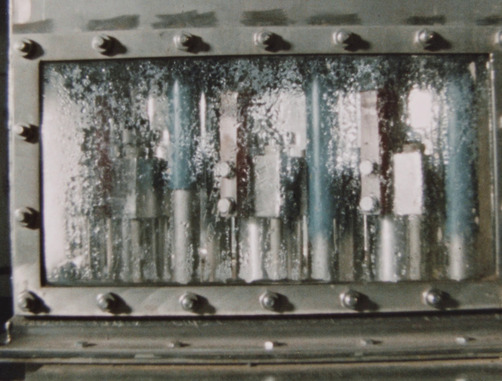

Catalog description: This film depicts the growing need for nuclear power and describes the features of heavy water reactors for use in power production. The development program conducted by the Atomic Energy Commission on this reactor concept is described in detail. Design studies performed on promising heavy water reactor concepts established the technical feasibility and economic promise of this concept. A number of research tasks in the fields of fuel design, engineering of low leakage components, studies of heat transfer and the physics of natural uranium heavy water systems were investigated in detail by Dupont and other research contractors to the USAEC. The facilities at the Savannah River Laboratory and at commercial laboratories used in this program are shown. Primary emphasis in the development program was placed on design of an inexpensive natural uranium fuel element for the heavy water reactor. Processes of fuel fabrication of both uranium metal and uranium oxide are described. To verify the results of the fuel development and other engineering programs a test reactor called a Heavy Water Components Test Reactor (HWCTR) was constructed at the Savannah River Plant. The film describes the construction of this reactor and outlines in detail the technical features and capabilities of the HWCTR and its special loop systems in demonstrating the heavy water reactor concept.

This is film 88394 in our catalog.

Stills from the film

See Also

- Austin, W., and D. Brinkley. “HEAVY WATER COMPONENTS TEST REACTOR DECOMMISSIONING.” Savannah River Site (SRS), Aiken, SC (United States), October 13, 2011. https://www.osti.gov/biblio/1027493.

- “Heavy Water Components Test Reactor Decommissioning - Major Component Removal.” Savannah River Site (SRS), Aiken, SC (United States), May 5, 2010. https://www.osti.gov/biblio/978453.

- Collins, James A., and Maxwell Gensamer. “Heavy Water Components Test Reactor: Condition of Reactor Vessel (Final Report).” Savannah River Site (SRS), Aiken, SC (United States), October 1, 1961. https://doi.org/10.2172/1891327.

- Guay, A. E. “Behavior of Metallic-Uranium Tubular Fuel Elements during High Temperature Irradiation.” Douglas United Nuclear, Inc., Richland, Wash. (USA), June 13, 1969. https://www.osti.gov/biblio/5099594.

- “HEAVY-WATER-MODERATED POWER REACTORS ENGINEERING AND ECONOMIC EVALUATIONS. VOLUME I. SUMMARY REPORT.” Du Pont de Nemours (E.I.) & Co. Engineering Dept., Winmington, Del., June 1, 1960. https://doi.org/10.2172/4133696.

- “HEAVY-WATER-MODERATED POWER REACTORS ENGINEERING AND ECONOMIC EVALUATIONS. VOLUME II. ENGINEERING STUDIES AND TECHNICAL DATA.” Du Pont de Nemours (E.I.) & Co. Engineering Dept., Wilmington, Del., December 1, 1960. https://doi.org/10.2172/4068768.

- Hood, R. R., and L. Isakoff. “Heavy Water Moderated Power Reactors. Progress Report for December 1959.” Du Pont de Nemours (E.I.) & Co. Atomic Energy Div., Wilmington, DE (United States); Savannah River Site (SRS), Aiken, SC (United States). Savannah River National Lab. (SRNL), January 1, 1960. https://doi.org/10.2172/4182427.

- Kiger, E. O. “OPERATIONAL SUMMARY OF THE HEAVY WATER COMPONENTS TEST REACTOR, OCTOBER 1961-DECEMBER 1964.” Du Pont de Nemours (E.I.) and Co., Aiken, S.C. Savannah River Lab., April 1, 1966. https://doi.org/10.2172/4541128.

- “LARGE HEAVY-WATER-MODERATED POWER REACTORS. An Engineering Feasibility Study.” Du Pont de Nemours (E.I.); Co., Wilmington, Del., November 1, 1964. https://doi.org/10.2172/4676628.

- Marshall, R. P. “ANALYSIS OF FAILED 17-4 PH BOLTS FROM THE HWCTR.” Du Pont de Nemours (E. I.) and Co., Aiken, S. C. Savannah River Lab., January 1, 1967. https://doi.org/10.2172/4503601.

- McKibben, J. M. “CORROSION OF EQUIPMENT IN THE HEAVY WATER COMPONENTS TEST REACTOR.” Du Pont de Nemours (E.I.) and Co., Aiken, S.C. Savannah River Lab., June 1, 1965. https://doi.org/10.2172/4584728.

- Quigley, H. C. “IRRADIATION OF A U-2% Zr FUEL TUBE IN THE VBWR.” Du Pont de Nemours (E.I.) & Co., Wilmington, Del., April 1, 1962. https://doi.org/10.2172/4818425.

Internal links:

- Our Digital Reactor History Museum

- Our Reactor Development History Page

- Our Old Videos page with a running list of the available and yet-to-be-scanned films out there.

If you’re interested in helping to get some of these scanned, check out our digitization GoFundMe and/or contact us!

About Dr. Nick Touran, Ph.D., P.E.

Nick Touran is a nuclear engineer with expertise in advanced nuclear reactor design, reactor development, and the history of nuclear power. After getting a Ph.D. at the University of Michigan, he spent 15 years at TerraPower in Seattle working on core design, business development, software development, and configuration management. He is now a consultant involved in advising and assisting numerous reactor development and deployment efforts. He is also a licensed professional engineer in Nuclear Engineering.

Nick has been active in public education around nuclear since 2006 as the founder of whatisnuclear.com. He has spoken at numerous institutions, schools, and public events, and was once featured on NPR’s Science Friday. Recently, he has coordinated the digitization of over 45 historical nuclear films.

Reader comments